BRINGING INNOVATION TO THE MUSIC INDUSTRY

5 LINE TECHNOLOGY | FORT WORTH, TX

Call Us

972-515-7730

Email Us

DESIGN

5 Line's award-winning staff engineers help entrepreneurs and manufacturers turn their innovative ideas into a finished product. We understand the characteristics and specifications of the products you are looking to create. Our expert team will help with ideas, 3-D modeling, engineering, drawings,

and develop prototypes for you to sample.

ENGINEERING & DESIGN SERVICES

POST PROCESS FINISHING

Our complete turnkey process can finish your manufacturing project with the latest, most accurate friction reducing plating, anodizing, lacquering, or precious metal plating. With the broadest range of engineered coatings anywhere, we can solve your most challenging friction, wear, contamination or release problem. Compliance with GSA standards and specifications.

-

Hand Sanding

-

Custom Color

-

Anodizing, Precious Metal Plating, Friction Reducing Plating

-

Corrosion Resistant

-

Friction Reduction

-

Clear Coat

REVERSE

ENGINEERING

Reverse engineering enables the duplication of an existing part by capturing the component's physical dimensions, features, and material properties. Typically, the demand for reverse engineering comes from clients who need to use existing "legacy" components as the basis for a new design or need to incorporate them with newly designed parts for which they have no CAD data.

5 Line can even help companies update old machines or machinery by reverse engineering needed parts. 5 Line is often engaged to help re-engineer or reverse engineer parts or machinery needed for manufacturers to produce items or raw materials.

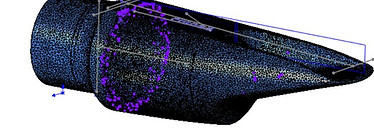

3D LASER SCANNING

At 5 Line Technology, we utilize 3D Laser Scanners to analyze and produce 3D representations of everything from instrument and accessory parts/pieces to musical environments (theaters, concert halls, indoor facilities.) We collect extremely accurate data (+/- 0.001”) on existing conditions which can then be used to construct digital, 3D computer models. These models can be used to optimize or alter the original design and to manufacture and assemble extremely accurate modifications for your instrument.

CT SCANNING

Computed Tomography (CT) scanning is the most accurate and versatile scanning technology available today for inspection and modification of musical instruments. CT scanning utilizes x-rays to produce 3D representations of both INTERNAL and EXTERNAL components.

⦁ Fast and accurate: With CT scanning, design and manufacturing requirements for both internal and external components are confirmed quickly and with the highest degree of accuracy (from 0 .0002 inches / 0.005 mm.)

⦁ Non-Invasive and non-destructive: CT scanning enables our technicians (and you) to see your instrument’s internal components in their functional position without requiring disassembly your horn. This allows us to identify misalignments with valves, tone holes/pads, and other issues in instruments.

⦁ Ensure quality modifications: CT scanning allows our technicians to ensure that your instrument’s modification performs exactly as expected and specified.

CAD DESIGN

For 20+ years 5 Line Technology has provided CAD engineering contract services for the automotive, aerospace, architectural design and structural engineering industries. Whether it is development and testing of prototype parts and pieces, bench-marking, or digital testing, 5 Line is your source for quality CAD design.

3D PRINTING

5 Line offers a number of different 3D printing technologies in metals and plastic.

CNC PROBING & MACHINING

Traditional probing is the most accurate process for reverse engineering with existing parts and pieces. CNC probing creates the most accurate digital file which can be optimized with CNC machining.

CASTING

Investment casting is an industrial process based on lost-wax or lost-pattern and is one of the oldest known metal-casting techniques. Within days of receiving 3D CAD data our printed patterns can be readied for metal casting with our 3D Printed Materials burning out just like wax.

LET US KNOW HOW WE CAN HELP

100 E Felix St. S Suite 102

Forth Worth, TX 76115

We can diagnose misaligned parts, leaks, manufacturing defects and other instrument malfunctions at the MOST ACCURATE level POSSIBLE TODAY WITHOUT ANY disassembly in some cases. We're there every step from reviewing and perfecting, manufacturing and going to market.